NFC RFID tracking is a great way to track your assets in real-time. It also helps you optimize supply chain flows on a local and global level.

NFC has a much shorter read range than GPS and requires less energy, making it ideal for asset-tracking applications. It is also secure, requiring an activation range that makes duplicating or hacking credentials harder. For quality NFC RFID tracking, check this out.

Cost-effectiveness

Many companies are interested in RFID tracking because it can reduce costs by allowing them to automate manual tasks. However, they must understand that RFID systems have fixed and recurring fees. Considering these costs, it is essential to determine whether or not RFID is an appropriate technology for their use case.

Many companies are interested in RFID tracking because it can reduce costs by allowing them to automate manual tasks. However, they must understand that RFID systems have fixed and recurring fees. Considering these costs, it is essential to determine whether or not RFID is an appropriate technology for their use case.

Passive RFID tags are inexpensive, running for less than a dollar each. However, more specialized tags may cost significantly more, mainly when used for metal objects or liquid-filled items. These prices can dramatically increase the total costs of a passive RFID system.

Another cost factor is the labour required to install and maintain the RFID system. This includes setting up the readers and laying out the network, which can take time. Also, suppose a company plans to use an RFID solution that requires cellular connectivity and GPS chipsets. In that case, the power consumption can be relatively high, leading to higher operating costs for the system.

Lifespan

RFID tracking helps organizations optimize supply chain logistics and inventory control and improve consumer engagement. It also allows for a better understanding of the carbon footprint of products, including the sourcing of materials, energy use during production, transportation, and end-of-life disposal.

The technology relies on radio-frequency identification (RFID) readers and tags with microchips encoded with digital information. The data is transmitted from the tag to the reader via radio waves and then sent to an asset-tracking system to be analyzed. For quality NFC RFID tracking, check this out.

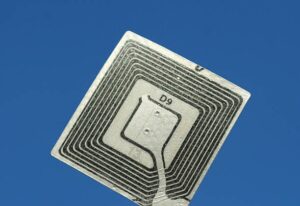

The RFID tag is attached to an item, usually a container or pallet. A fixed reader then scans it in a confined indoor space. The RFID antenna transmits the reader’s interrogation signal to wake up the microchip and send a response to the reader. The antenna can vary in size and design, depending on several factors, such as the read range and environmental conditions.

Regulatory compliance

Many RFID systems use radio transmitters and receivers that must comply with local regulatory bodies. Some may require certification to UL (US) or CE (Europe), while others are exempt from these requirements. Depending on the frequency range of the hardware, some systems also need to be regulated for global compliance.

NFC RFID tracking helps companies meet safety and compliance standards, such as ensuring that equipment or vehicles have been inspected on time. It can also help with reporting regimes, reducing waste and improving efficiency.

Temperature-sensing RFID tags provide accurate and accessible data collection for many different applications. These include asset tracking, cold chain monitoring, manufacturing, data centre monitoring and maintenance, and greenhouse monitoring. The sensors are battery-free and can be read from a distance or up close with a smartphone app or scanner. They can even be placed on metal surfaces, like wires and cables, to monitor temperature and prevent corrosion. The labels are also biocompatible, making them safe for pharmaceuticals and biological samples.

Visibility

RFID technology uses a reader, antenna, and transponder (or tag) to track assets and inventory. RFID tags are small, battery-free devices with unique identifiers and can store varying amounts of information. They can be read by a radio frequency-based reader within a short distance, typically up to 30+ meters. For quality NFC RFID tracking, check this out.

The technology also provides a centralized system for managing data. This enables asset managers to gain insight into the status of assets and inventory, making it easier to locate them when needed.

In addition to enabling greater visibility, NFC RFID tracking can reduce costs. By integrating RFID with an ERP or WMS system, you can automate tracking processes and reduce manual errors. Additionally, NFC tags can be used for smart ticketing, which helps you avoid overpayments and ensures a better customer experience. Lastly, NFC can make payments quickly and easily with a simple tap on an NFC-enabled device. This makes it more convenient for customers to pay and saves staff time.